Leak Testing with Furness

Featuring world-leading sensitivity, a diverse range of testing capabilities and flexible connectivity options, our Leak Testing range ensures manufacturers have the tools they need to ensure product quality.

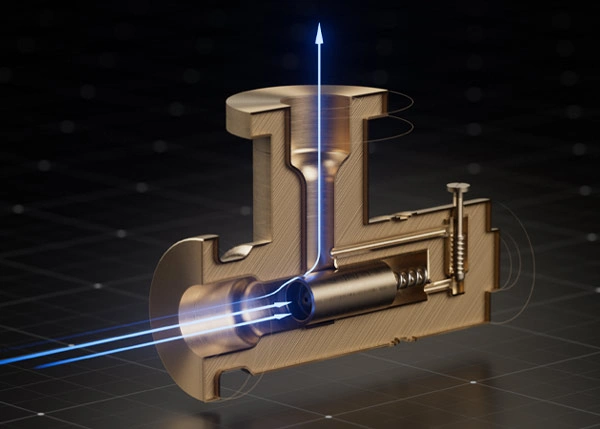

Applying pressurised air or gas to a product is one of the most widely-used, accurate and convenient leak test methods, finding use across the manufacturing sector to ensure product quality and safety

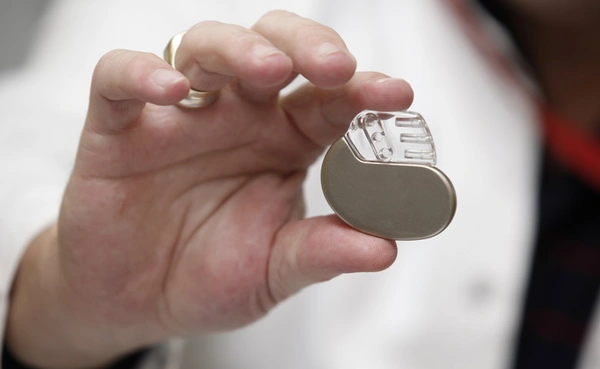

Furness Controls are experts in the manufacture of differential pressure transducers in the low-pressure range, with unparalleled sensitivity. As a result, our leak testers can measure a pressure drop in a test item of only 0.1 Pa. This can translate into a leak rate of only 0.01 ml/min for real-world test items.

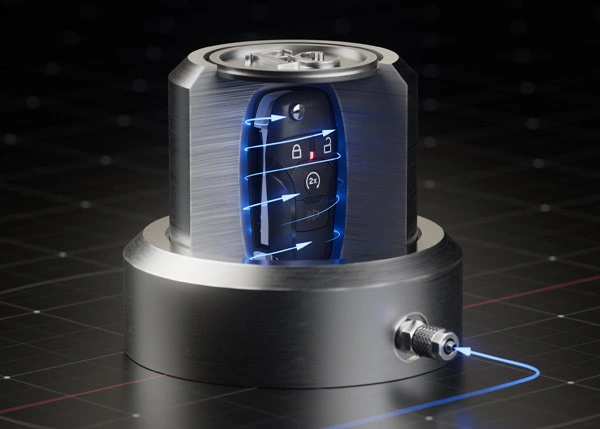

Our leak testers offer a wide range of pressure and leak ranges and can combine differential pressure decay tests with other test methods such as blockage tests, sealed-part tests, bell tests and ramp tests in complicated sequences.

No expensive tracer gases and no contamination with fluids

Results from testing with pressurised air directly relate to required leak rates for a range of fluids and gases

World-leading sensitivity and a range of test pressures allow test times down to milliseconds

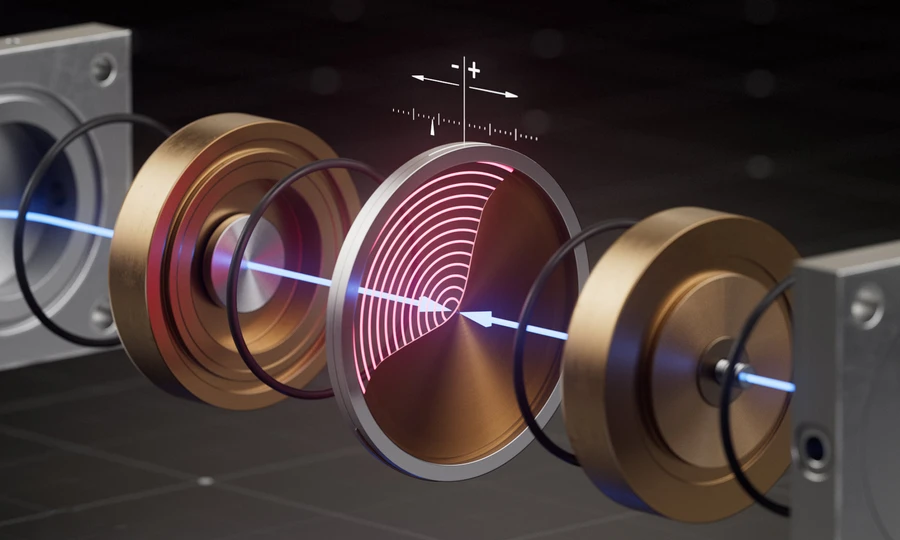

The use of differential measurement to detect pressure decay in test items is one of the most sensitive methods of leak testing, and the most commonly applied using our range of production line leak testers

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua in reprehenderit in voluptate velit esse cillum.

Test air-tightness of products that are already hermetically sealed

Check activation pressures for devices such as pressure-relief valves and actuators

Include checks for minimum flows alongside leak tests

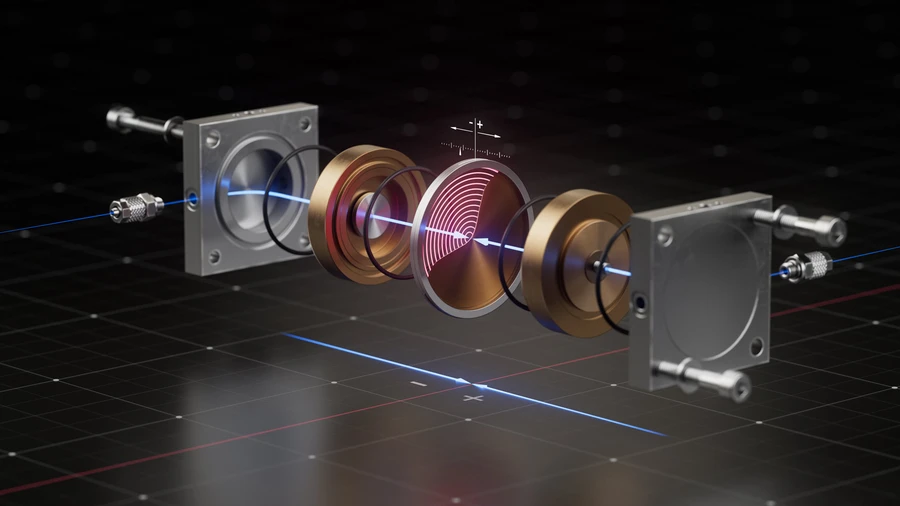

Two pressure sensors are used. The first an absolute sensor with a span to encompass the range between atmospheric and the required test pressure, and the second a highly sensitive differential pressure transducer that can detect small pressure changes between the test item and reference volume.