Key Features

- A unique primary standard for low-pressure scenarios

- Pressure calibration range from 0.001 Pa to 44k Pa

- Typical uncertainty of ± 0.005 % reading + 0.02 Pa

- Used worldwide in national & accredited laboratories

- New 2017 version now available

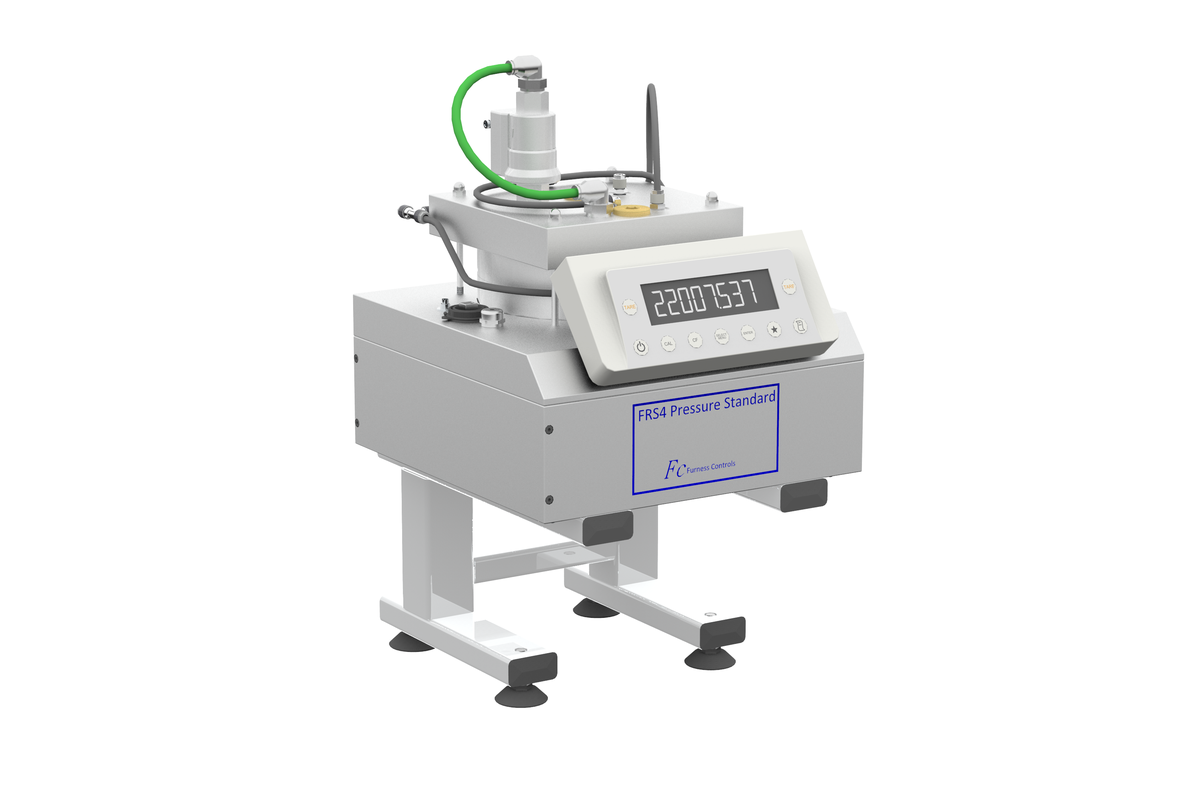

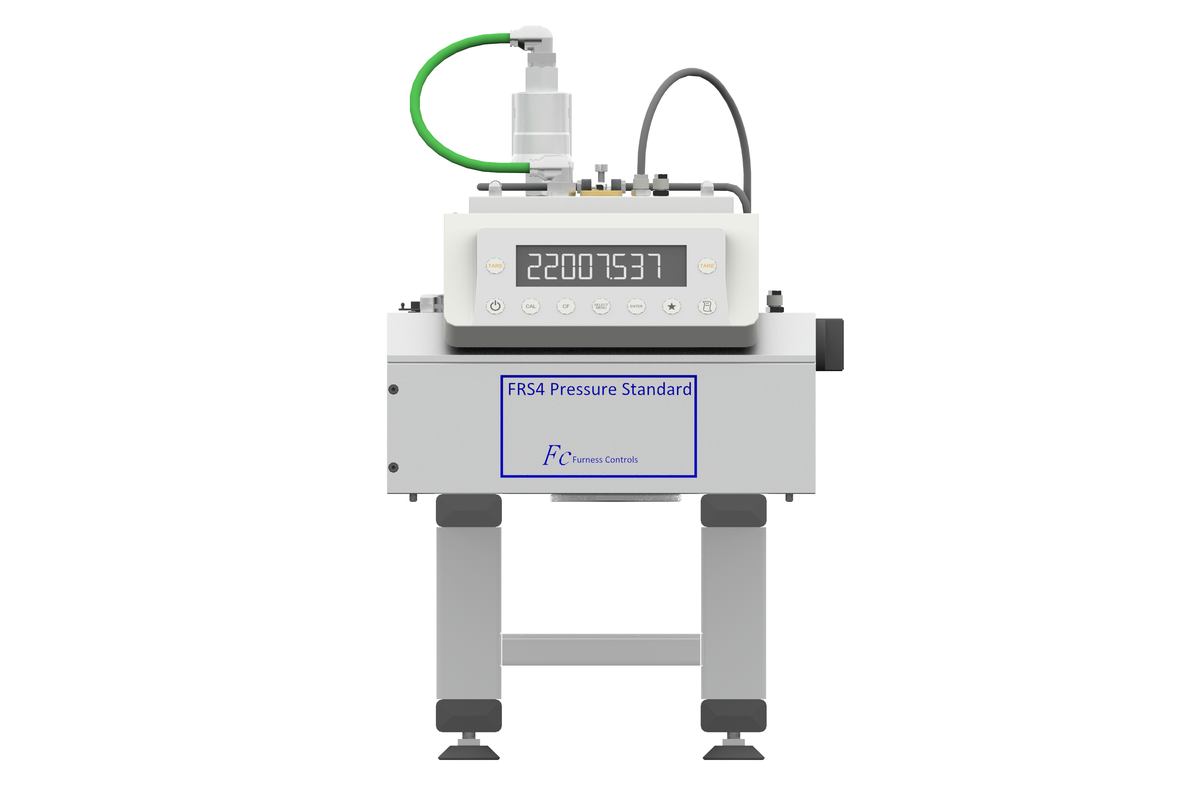

Used in laboratories throughout the world, the Furness Controls Reference Standard (FRS4) is a high-resolution low-pressure standard directly traceable to national standards via mass and linear measurement. The instrument is the gold standard for the calibration of both gauge pressure and differential pressure. Its unique design allows high levels of accuracy at very low pressure levels, in the range where competing instruments begin to experience uncertainty.

Producing a standardised pressure requires precise knowledge of the metrics of the physical components involved. The FRS4 uses regulated air flow over a piston with precisely known mass and dimensions, a high accuracy digital balance, and a precision control unit. With these components the FRS4 is able to generate a precise differential pressure for use in the calibration of a multitude of devices, such as capacitance diaphragm gauges, and low-pressure transmitters and transducers.

Precise Construction

The piston is suspended centrally in a cylinder using a parallelogram suspension system, and both are precision-engineered from Invar, a nickel-iron alloy with a low thermal expansion coefficient. This gives an area expansion coefficient at room temperature of around 4 ppm.

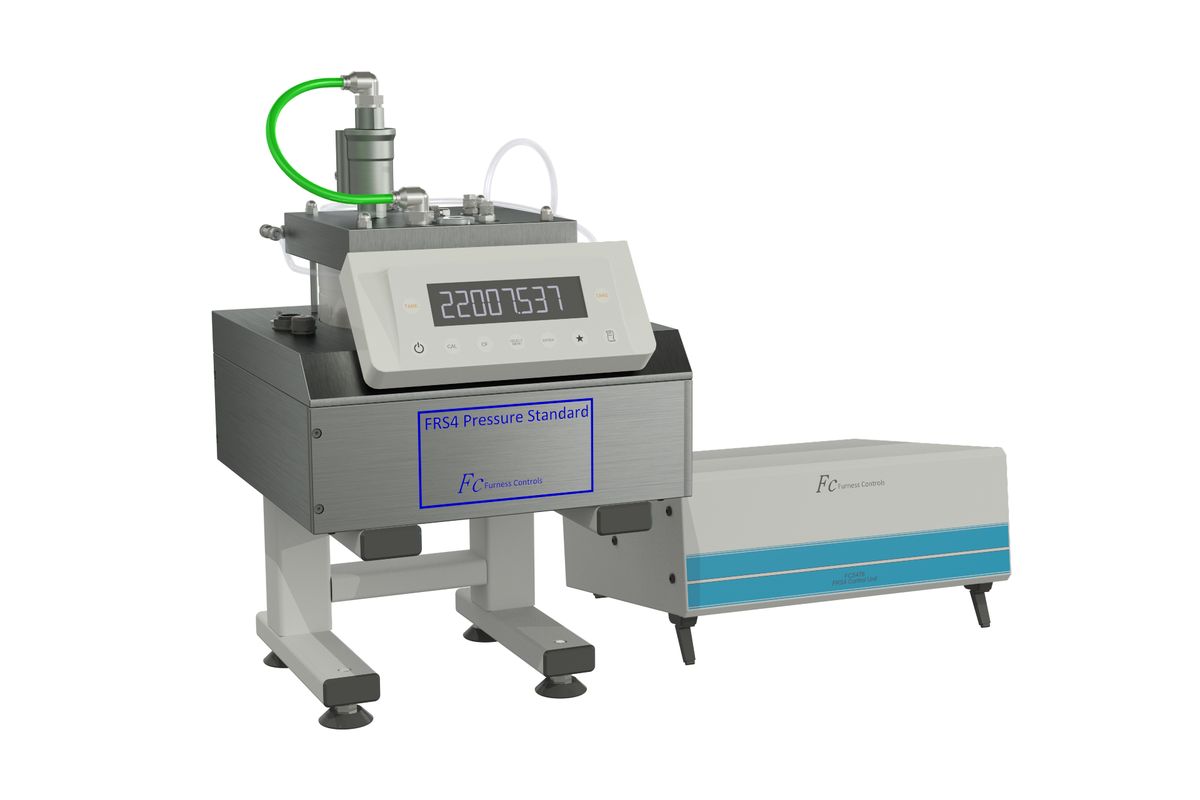

User-friendly

To complement the FRS4 pressure balance, the FCS476 control unit can be used to provide automatic pressure control from a PC.

Using the shock resistant transport case, the FRS4 is easily transportable, making it useful for the inter-comparison of other pressure standards with are not so readily moved.